Yes:

pyramids in plural. This post will compare the main Louvre pyramid (the one we all remember) with the inverted pyramid, less known but equally noticeable. Both are of course part of I.M. Pei's plan for Le Grand Louvre in Paris, commisioned by President Mitterrand as the first of his 'Grand Ouvres'. But as we will see the similarities between the two end right there. The main pyramid epitomises the end of the

structural frame era, while the inverted pyramid represents one of the first examples of our time, the supremacy of

structural glass.

|

| An unusual view: the main pyramid seen from the top of the inverted one |

The main pyramid - together with its three small siblings surrounding it - was finished and opened to public in 1989. The inverted pyramid was not completed until 1993. On the earliest sketches made by I.M. Pei back in 1983 the main pyramid, surrounded by the other three and the pools was already there. The inverted pyramid came slightly later in the plan, around 1985, as a standing point marking the entrance from the underground and the parking.

|

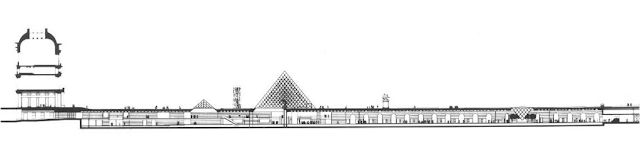

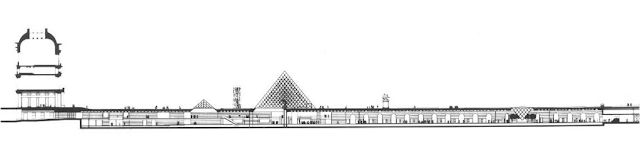

| The main pyramid (centre) and the inverted pyramid (right). The underground entrance takes place from the right. |

Pei wanted the main pyramid to be the new entrance to the Louvre, so that people had to wait on the Napoleon court to enter the museum. But this proved not enough to manage the thousands of people arriving every day. Soon predominance was given to the underground entrance, be it from the tube line of from the parking lot. Both coincide precisely at the inverted pyramid, so that it now becomes the first glass feature to be discovered by visitors.

|

| The inverted pyramid between the gardens and the main one |

Why are these two structures so different? Aren't both of them just glass pyramids? Well, not exactly. The first difference is their size. The main pyramid has a square base of 35.4m and a height of 21.6m, while the inverted one has a square base of 15.5m and a height of just 7m. Another reason for the two structures to have been designed different is wind load. The main one has to withstand strong wind loads that don't exist in the case of the inverted pyramid. To be precise, the inverted pyramid top side (which by the way is a very low pyramid in itself) only has suction loads due to wind. But the main reason for these two structures to be remarkably different is a fact of evolution: the engineers who designed the main pyramid remained under the old paradigm of

glass as an infill; the engineers that were given responsibility to design the inverted one were pioneers of the new paradigm of

glass as a structural element.

It has taken me a while to find out who the main actors are in this play in two parts. From the architect's side it is clear : I.M. Pei from Pei & Partners (now

Pei Cobb Freed & Partners) was the design principal. Second in charge was Leonard Jacobson, although the design architect in charge of the pyramids was Yann Weymouth. Yann's sketches between 1983 and 1986 are the visual history of the design process, both in general and in its details.

|

| Yann Weimouth and I.M. Pei on site during the main pyramid construction |

|

| Studies for tension fastening of the main pyramid. The left version was the selected one. Sketch by Yann Weymouth, April 1985. |

Yann, who was fluent in French, lived in Paris between 1984 and 1990. The associate architect (the French local) was Michel Macary.

|

| The 'serres' at La Villette by RFR, 1982-86 |

Now comes the conundrum of the story: the engineer's selection. The best engineering firm in glass tensed structures worldwide was at the time very active in Paris:

RFR, Rice Francis Ritchie. This team of one Irish engineer - Peter Rice - and two British architects (Ian Rithchie was 100% architect; Martin Francis was partly a yacht designer) was created in Paris in 1981. RFR had successfully completed the 'serres' at the Parc de la Villette between 1982 and 1986, so they had to be well known to Michel Macary or to Emile Biasini, Mitterrand's man in charge of the whole project. How then RFR were not given the task of engineering the pyramids? The answer - as much as I can guess - must be found in I.M. Pei's contractual conditions: Pei was made 100% responsible of the design without any interference from French officials or local establishment. This included of course the selection of his engineers - which would be

his and not a French firm if he wanted to build his Pyramid as pure as he wanted. It is a real pity that Pei was not right in this point - surely without knowing it at the time.

So the selection for the engineer was made by Pei, and Pei chose the Canadian firm of

Nicolet Chartrand Knoll Ltd. What did this firm exactly do at the project? Their role seems to be clear for the large underground concrete structures. Let's not forget that the main pyramid sits atop a 2m-thick concrete slab with large spans. The stair connecting the Napoleon court with the bottom level is also a feat, with its 540º self-supporting curve. As Nicolet Chartrand Knoll refer to the Louvre pyramid in their webpage French version "

The scope for the structural engineer, as bluntly expressed by the architect I.M. Pei, was that of building a structure as transparent as technology could reach. Through a close collaboration between the architect, the structural engineer and the other professionals it was possible to reach a successful outcome. Out of about 25 different structures which were studied, one was finally selected ".

Now, letting aside the fact that they studied many options, was the final structure of the main pyramid as transparent as technology could reach by 1986? I humbly disagree, and it seems that Mr Pei was not too impressed by its transparency either. The main point is a conceptual one: this is not the design of a glass pyramid, but the design of a steel pyramid clad with glass. Glass is just filling the space between the stainless steel struts, it is not taking any structural role. As

Mick Eekhout - the Dutch structural glass specialist - would put it, the main pyramid is an example of

space frame with integrated glazing. The two details below compare a structure of the mid-80s with the main pyramid detail:

|

| Left: a Mero space frame with integrated framing. Right: the top detail of the main Louvre pyramid |

The Louvre solution is fairly more

integrated than a space frame with a separate glazing as the

Mero structure with glass on top. The outer mullions have disappeared and now a fairly thin aluminium profile is receiving the glass panels. But the glass is simply sealed at four sides with silicone; it is not making part of the structure at all. Suppose we take out all the rhomboidal glass panels: nothing would happen to the structure, the pyramid would remain in place. The pictures from construction period show this quite clearly. Images below have been taken from the book 'I

.M. Pei. The Louvre pyramid' by Philip Jodidio, Prestel. It also has great sketches from Yann Weymouth.

|

| Glass being installed at the main pyramid. There was practically no internal scaffolding in this picture. Notice the bespoke cradle to attach the suction cap to the pyramid. |

|

| Scheme of the steel structure of the main pyramid. Left: steel tubes in rhomboid shape with cables and stiffeners. Right: the same with glass already in place. |

|

| Stages of glass installation on the main pyramid |

If the main Louvre pyramid was an American-Canadian design, how come did RFR start working for this pyramid - and yes, much before the inverted one was started? There are two reasons for that, and probably the two were required. The first reason is to be found in the (French) facade contractor:

Eiffel Construction Metallique, precisely the same facade contractor that had undertaken the building of the serres at La Villette some years before. The Eiffel guys entered the design team for the Main Pyramid when it was still in the drawing table - remember: 25 models were studied before concluding on one. They must have seen that the Canadian engineers, expert as they were in concrete structures, found themselves a bit lost with the cables and rods of the pyramid. So Eiffel managed to sub-contract RFR as their experts to discuss design subtleties with the Canadians.

|

| Node detail with tubes, bars and cables |

The second reason was Peter Rice. He was at the time part of two companies in parallel:

Arup - his first employer - and RFR - his new baby. A strong Arup engineering and lighting team, directed by Rice, was working at the same time on the Richelieu wing of the Museum, taking care of the glazing of the three big courts (5,000m2 and 450 tons of steel in total) and of the natural lighting strategies for the whole Richelieu wing. Thus, Rice was already known to and appreciated by the 'proprietaire'. I can imagine Peter Rice inviting Emile Biasini (the boss on site) to take a taxi and visit La Villette sometime during the works.

Since Rice was engaged with the Arup team, the RFR consulting work for the main pyramid (remember, under the hat of the facade contractor) fell on Martin Francis. Martin was an architect but also a yatch designer. The whole concept of suspended glazing and stainless steel cables owes in fact a lot to the yatching world of mast connections. As part of his sailing activities Martin knew of an American company who were masters in stainless steel rods, cables and riggers for naval architecture. The company name was

Navtec and Martin Francis' colleague there was Tim Eliassen. This becomes interesting, and a prove that mixing technologies is always productive. Eliassen, who had studied aeronautical engineering and graduated in nuclear reactors had cofounded Navtec to end up immersed in the world of large sailing yachts, America's cup boats and the like.

|

| Inner transparency, so much sought after by the architects, depends largerly on the point of view. |

According to

Mic Patterson (himself a good friend of Tim's and as such a reliable source), in 1987 Elliassen received a call from Francis telling him that there was a project in France that needed his involvement. The main pyramid became the first architectural project for Navtec, where they provided about 3,800 'short pieces of yatch rigging' to Eiffel. After completing the Louvre pyramid Eliassen tried - unsuccessfully - to convince his colleagues of Navtec to enter the business of glass architecture. Navtec comment at the time, according to Patterson, was unforgettable: "roofs leak, you get sued". So Eliassen founded

TriPyramid Structures - notice the relationship between the name and his first job - in late 1989 and started a long line of high-profile projects, helping US architects to master in the new science of glass and steel. But that's another story.

|

| The complexity of connecting elements next to the bottom of the pyramid. Notice the air fans pointing towards the inner face of glass, intended to reduce the risk of condensation. |

A side note about glass selection for the main pyramid will give perspective on how much things have changed since the mid '80s in glass technology. Pei wanted a glass as clear as possible, and he was sure that the required laminated thickness (and even more in diagonal views) would be seen as green form the outside. So under his pressure a new manufacturing process was devised using Fointanebleau white sand -that is, sand very low in iron content - in collaboration with the French firm

Saint Gobain. Possible it was, but expensive: the cost of producing a small batch of low-iron glass was huge at the time, and the big boss at Saint Gobain wasn't willing to stop the furnace and introduce such an order. Pei has declared (it's in Jodidio's book) that he went to Mitterrand in person in order to get the glass he wanted. Those were the days: the Emperor stopped the furnaces and glass for the pyramid came out as clear as it had to be...

|

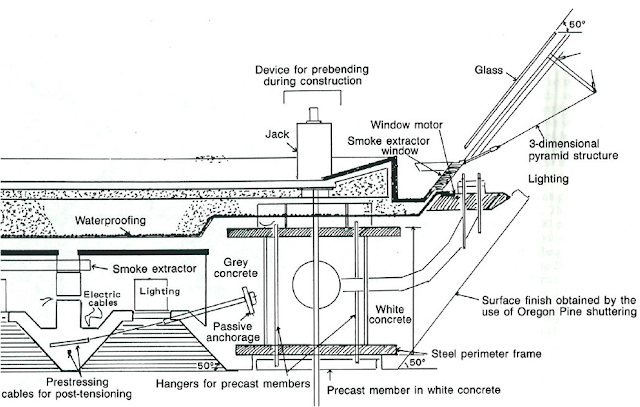

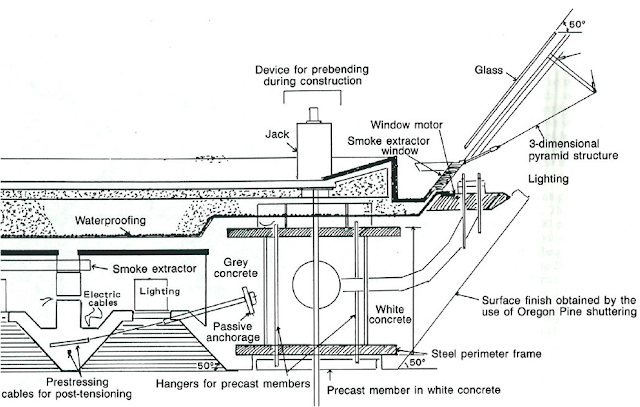

| Section of the concrete slab below the glass pyramid. This was the kingdom of Nicolet Chartrand Knoll, the Canadian engineers who started designing the pyramid concept. |

So the main pyramid ended as best as it could, still not as 'trasparent' as Pei wanted, but it would have a great influence - much larger than the serres of La Villette - in expanding the word of the new structural glass facades to the world.

Now, Martin Francis had shown Pei how useful it had been to have RFR on board for the main pyramid, and Pei awarded them with the contract for the inverted pyramid. For RFR the next logical step in the linear sequence of the history of glass had to be the disappearance of mullion frames, elevating glass to the primary structural element of the builiding's skin. And this is exactly what happened with the inverted pyramid: the flat, clean glazed surfaces of La Villette lost their ugly steel tube edges and became a pure glass-enclosed volume. The inverted pyramid is to structural glass what the Seagram building was to the history of curtain walling: the culmination of a de-materialization process that had taken years to achieve. And, Pei permitting, the main pyramid with all its glamour would be nothing but the Lever House, located - as its sibling - just some feet away from the real jewell...

Enough for this post. It's too much text already. Let me finish with some good images and drawings of the inverted pyramid. From the heights of our age it's easy to read and to understand how it works. It surely must have been painful to design, but there it will remail, the light of a candle, forever.

|

| Inverted pyramid as seen from the Carousel |

|

| Inverted pyramid: section and structural diagram |

|

| Inverted pyramid from below |

|

| Inverted pyramid: more structural diagrams |

|

| I.M. Pei at the bottom of the inverted pyramid |

|

| Inverted pyramid: the square brackets support the top square glass units while the cross brackets support the sloped rhomboid glass units. |

|

| Me as Peter Rice, hanging from cables... |

|

| Detail of the top glass brackets. Each glass unit is glued to one side of the bracket at each corner. Slope is 4º for water drainage. |

|

Detail of the side glass brackets. Each glass unit is drilled at the corners. The bracket is a mirror piece to avoid swinging and provide additional stiffening.

|